Starnet Commercial Flooring, the world’s largest network of full-service independent flooring contractors, announced today that DMA Floors has joined ...

Recent Blog Posts

DMA Floors News and Helpful Tips

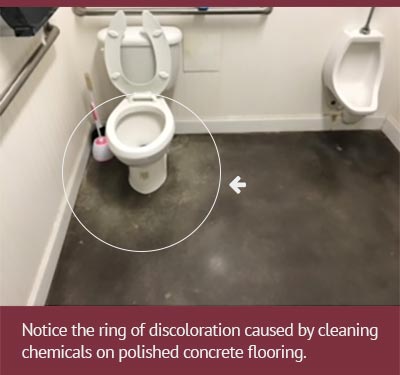

We love to polish concrete, but we also know that polished concrete is not the best option every time. There are several places where polished concret...

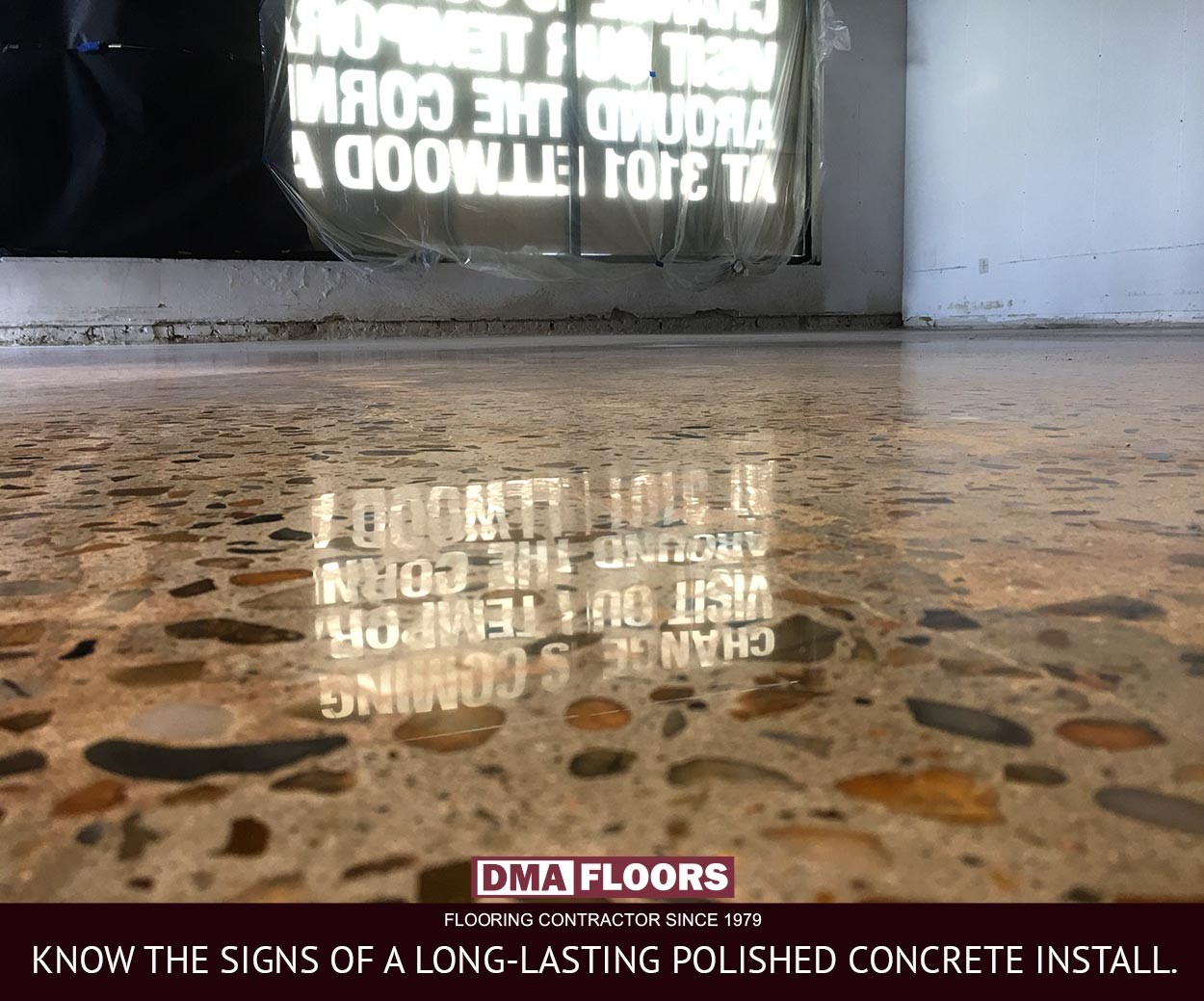

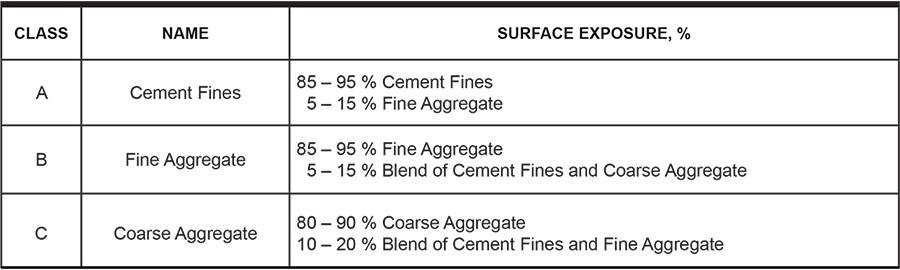

Polished floors are popular because they are durable and beautiful. You see them in restaurants, retail stores, offices, government buildings, public ...

There are many floors sold as polished concrete that will dull/wear out quickly because they were not installed correctly. They look good when the job...

Epoxy Flooring and Polished Concrete Divisions DMA Floors is excited to announce that Paul Coviello has joined our team to meet the growing need for e...

Covenant Woods in Mechanicsville, Virginia renovated their Lodge in June 2020. They elected to remove carpet and modernize the common areas to a glue ...

The National Shrine of Our Lady of Walsingham at Saint Bede Catholic received a complete interior renovation. This project began January 27, 2019 as a...

Azura Vascular Care | DMA Floors Azura Vascular Care understands that facility management contributes to the quality of patient safety. While the VHHA...

The days of “it’s just flooring” are long gone. The flooring of today has attributes that take into consideration such qualities as acoustics, comfort...

DMA Floors is pleased to announce the successful completion of the Patrick Henry Building, 3rd floor, contracted through the Department of General Ser...

For the first time in 30 years, the annual supply volume of apartment rentals has peaked due to lifestyle renters: people who rent by preference, not ...

Sheehy Toyota of Stafford is not your typical service department. They handle everything from preventative maintenance to major engine repairs. They&n...

By accepting you will be accessing a service provided by a third-party external to https://www.dmafloors.com/